Control screen: 7-inch control screen, computer intelligent control

Machine features: Safe operation, high efficiency, energy saving, environmental protection, unattended, precise temperature control, high quality and worry-free

Application field: it is specially used for drying grains, coffee beans, wheat, corn, soybeans, etc.

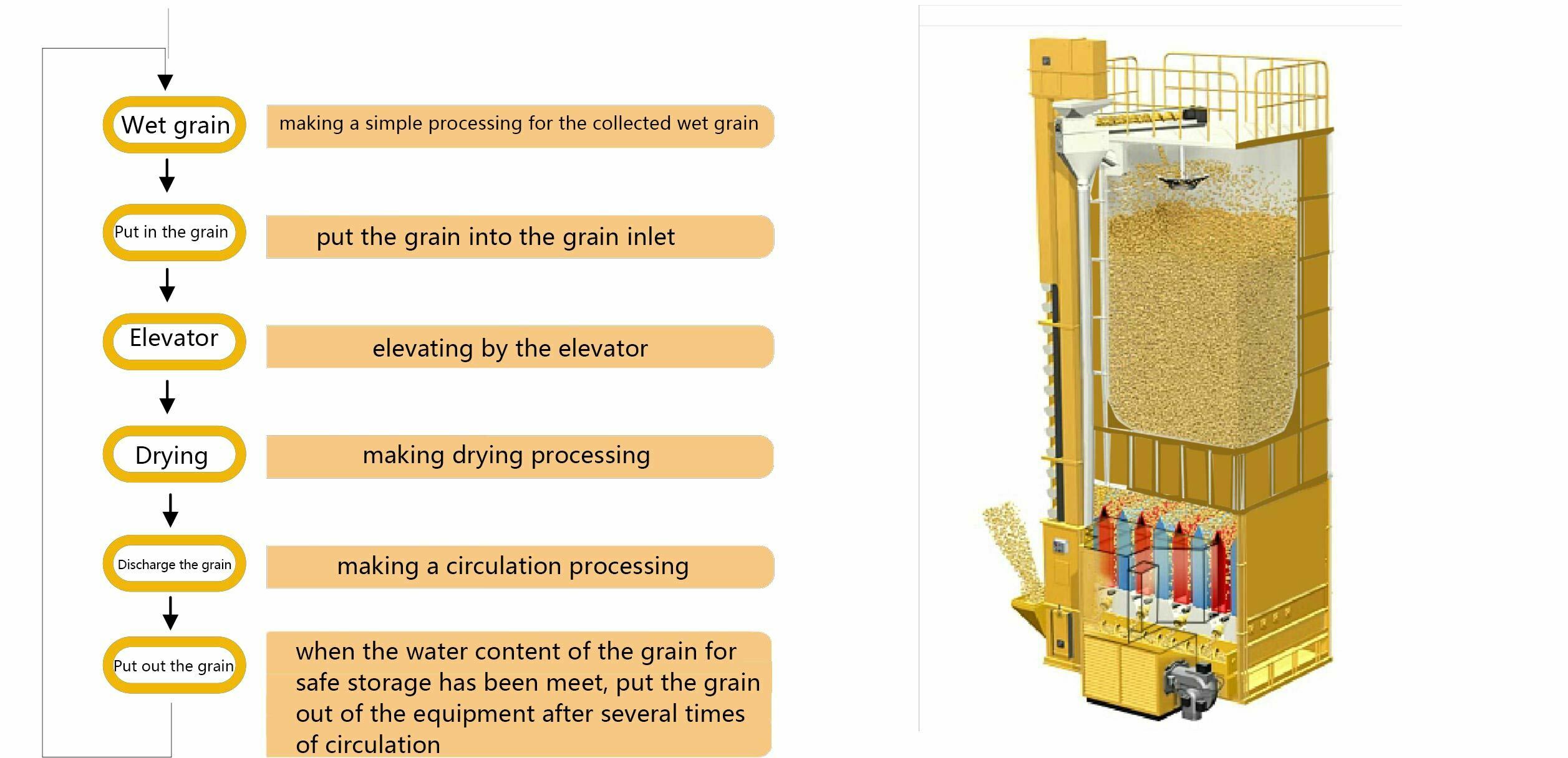

It adopts mixed-flow drying process, and the cleaned grains are fed into the dryer by a hoist. The grains flow continuously from top to bottom of the equipment by their own weight, and the tempering and drying process are realized during this flow process.

The hot air can flows in the same or opposite direction of the grain, which is called mixed flow. By adjusting the temperature of the heat pump dryer, when the hot air passes through the grain layer, it transfers heat and moisture with the grain. This means the hot air transfers the heat to grains, and the grain increase their temperature naturally. When the grains are heated, the water evaporates into the air and becomes exhaust gas. Reasonably matching the air volume of the induced draft fan to realize various drying temperatures and to control the ratio of air volume to grain. By adjusting the speed of the grain discharge motor, the residence time of the grains in the drying section is controlled, and the dried hot grain flows down to the tempering section. The temperature and moisture content of the inner and outer layers of the grains tend to be balanced after the tempering stage, therefore, it not only achieves moisture uniformity of the whole batch of grains, but also achieves the purpose of high-quality, high-efficiency, and energy-saving drying.

1、Heat pump drying mainframe:it mainly used for connecting the drying tower, the heat source is to absorb the air and then use it for compression, and then generate gas with high temperature and high pressure.

2、Drying tower:Grain dryer equipment is divided into heat source and drying tower, the drying tower transports our grain to the drying area, and then drying along with the belt and flow down. After the drying is completed, it will enter into grain discharge area for discharge

1.Low crushing, less failure, less brown rice, fast drying speed and fast discharging.

2.Safe and worry-free—no fuel and no burning; no light fire, not easy to lead tofireaccident, and mush safer..

3.Save labor and effort—drying is automatically completed, the whole process is protected. Automaticallyshutdown when the drying iscompleted.

4.Easy to operate—large screen display, one-key operation, convenient and efficient

5.High quality of grains—real low temperature drying; precise moisture control; no harmful residues added to the grains; highquality.

6.High-efficiency and energy-saving—it adopts air energy technology transplantation application, which consumes 1 part of electric energy toproduces about 4 times ofheat energy. It is more than 80% of fuel can be saved compared with coal-fired drying.

7.Green and environmental protection-it usesheat pump technology to achieve zero emissions; no pollution to the atmosphere,soil and water sources, and zero contribution to PM2.5.

8.Strong adaptability — it can be used in a wide range of ambient temperature from -5°C to 40°C; and can work under conditions with high ash content.

9.Heat pump transformation—The heat pump hot-air blower can replace the existing burner or combustion furnace. It is atransformation of the existing dryer.

10.Automatic dust collection — it adopts original dust collection technology, so that the heat pump can work in an environment with a lot of dust.

11.Unique drying tunnel—uniquedesign withlarge drying area and large air volume, which is equipped with emergency grain unloading port and straw removal port at the tower bridge.

12.Unique dust exhausting method—dust exhaustingis more thorough, and the food is cleaner.

13.Environmental protection and dust collection—Shuntec has conduct independent research ondust collection equipment that does not discharge ash, thus drying grains will no longer need to worry about discharging too much ash. Users can purchase environmental protection dust collection equipment.