The SHUNTEC belt dryer is a fully automated, factory-assembled modular sludge dryer system. Sewage sludge drying reduces transport and disposal costs. We are offering not only products but solutions for sustainable development.

The energy-saving low-temperature dryer developed by Shuntec has the characteristics of stable performance, safety and efficiency, energy saving and environmental protection, high intelligence and long service life. It has been widely used in municipal sludge, industrial (pharmaceutical, chemical, electroplating, dyestuff) , organic soil, tailings, etc.), agriculture and other fields with drying needs. It can directly dry materials with a moisture content of ≤85% to a moisture content of 5%-30% to meet your different drying needs.

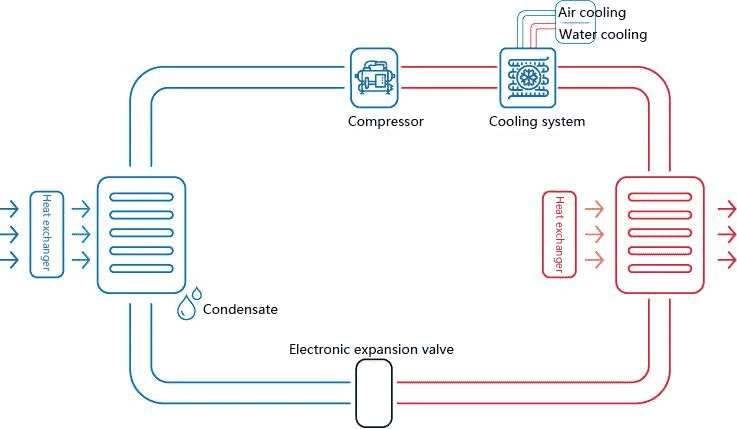

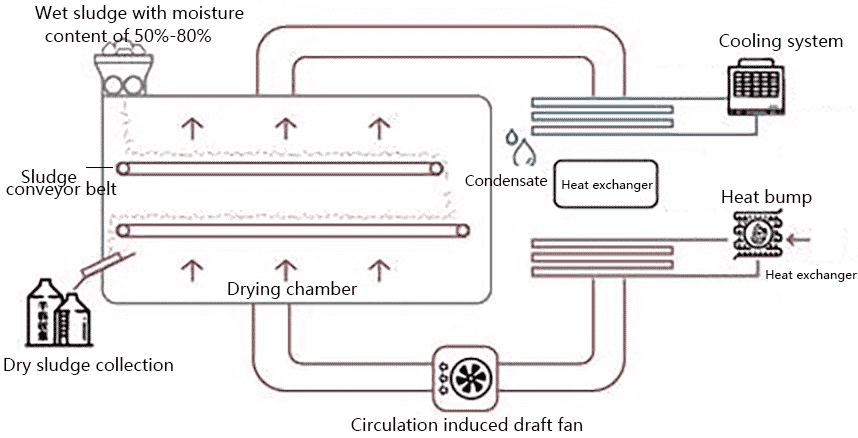

A gradient cooling system is used to cool and dehumidify the hot and humid air from the drying chamber, and the refrigerant absorbs the condensation heat (latent heat) of the water vapor, and is collected by the compressor, and then the dehumidified air is heated by the condenser. It is a combination of low temperature evaporation (dehumidification drying) and heat pump (energy recovery), and the thermal energy (latent heat) is recycled all the time during the drying process.

The energy-saving low-temperature dryer independently developed by Shuntec Environmental Protection uses the principle of low-temperature evaporation heat pump. The condensation heat absorbed by the heat pump acts on the wet material through the heated air through the induced draft fan, so that the moisture of the wet material is vaporized to achieve the purpose of drying the material. The whole system adopts a closed design, energy saving and environmental protection, no heat loss, and 100% latent heat recycling.

Our company is responsible for the equipment manufacturing, installation, and debugging of the equipment from the low-temperature drying machine silo to the low-temperature drying and discharging; Party A is responsible for connecting the main electric control box of the sludge drying equipment. within 1 meter; civil works shall be the responsibility of Party A.

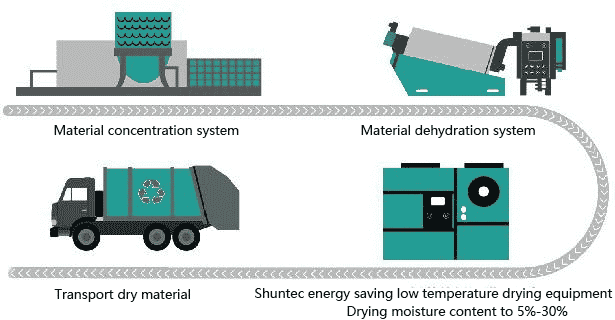

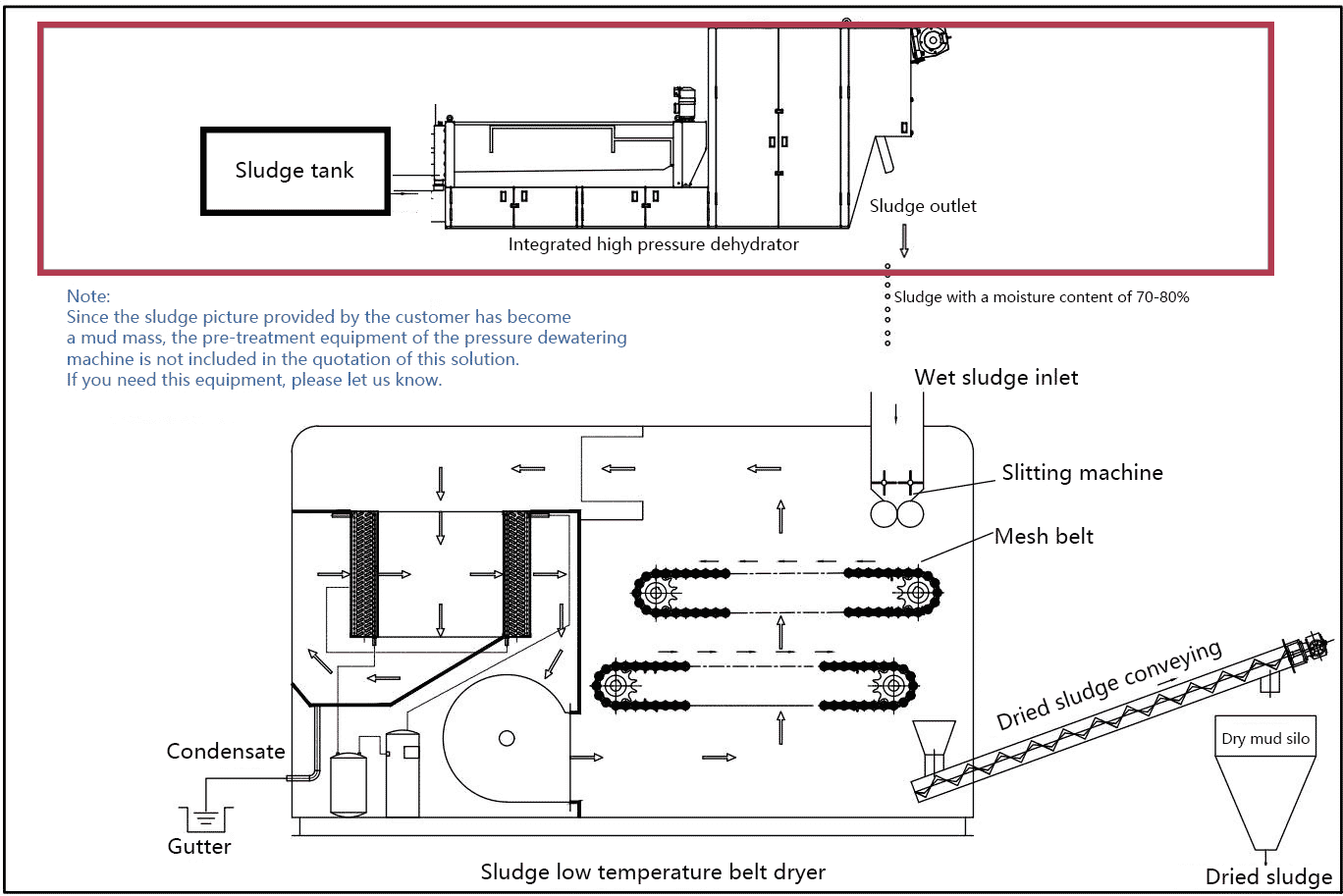

If the sludge is directly extracted from the river, it needs to be dewatered by a pressdehydrator and filtered into a sludge with a moisture content of 70-80%.

The sludge with a moisture content of 70-80% is placed in the wet silo and transported to the scraper by a double screw conveyor.

The scraper conveyor lifts the sludge to the wet sludge inlet of the dryer.

The wet sludge is cut into strips by the slitting machine and evenly falls on the mesh belt.

The wet sludgeflows on the double-layer mesh belt and is continuously dried by the hot air.

The dried sludge is transported to the drymud silo by the dry screw conveyor.

Transport away the dry mud.